Equipment such as flotation equipments, ball mills, jaw crushers, and extra play critical duties in the removal and handling of minerals. The flotation machine, for example, is utilized to separate valuable minerals from ore, utilizing the concept of hydrophilicity and hydrophobicity to promote splitting up.

Just as vital is the ball mill, a vital part in mineral handling and grinding. This machine finely grinds products by rotating a cyndrical tube with grinding media, normally steel balls or poles.

Jaw crushers stand as one of the primary devices in the crushing phase of ore handling. The hardness and strength of products dictate the certain configuration of the jaw crusher, making sure that it can properly satisfy the needs of various application types, varying from quarries to recycling plants.

Following the jaw crusher in the process chain is the impact crusher, typically used for tertiary and second crushing. One of the significant advantages of impact crushers is their capability to create top notch accumulations, many thanks to their carefully tuned layout that creates cubic-shaped outputs, reducing the need for extra processing.

In contemporary accumulation manufacturing, sand making makers have actually handled an essential duty. As the need for top notch made sand remains to expand, these equipments aid in the manufacturing of sand from rocks and crushed rock, considerably improving material quality. Sand making devices utilize vertical shaft impact technology, leading to the manufacturing of well-graded, regular fragments. With innovations in modern technology, these makers have actually ended up being much more efficient, allowing drivers to maximize using resources while minimizing waste.

Cone crushers are one more essential piece of tools in the crushing process, particularly when managing high-capacity procedures. Designed to take care of unpleasant and hard materials, cone crushers make use of a combination of compressive and shear forces to squash material. Their durable style and progressed innovation allow for greater throughput and effectiveness, driving down operation prices while still offering reliable result, important for fulfilling the demands of various jobs.

After the crushing and sizing processes, sand washing makers come right into play. By utilizing numerous washing and screening methods, sand washing machines generate cleaner sands that not just boost high quality but also boost the longevity and stamina of concrete and various other products.

In recent years, the mobile crusher has actually obtained recognition for its versatility and comfort. This mobile machinery permits operators to crush and refine products on-site, significantly decreasing transportation prices and enhancing flexibility in operations. Suitable for quarries, building and construction websites, and even recycling jobs, mobile crushers included numerous arrangements customized to specific crushing applications. Their ability to operate in different atmospheres, paired with technical innovations, positions them as an important tool in contemporary aggregate handling.

In the more comprehensive context of mineral handling, the crushing plant acts as the accumulation handling center. Commonly consisting of numerous kinds of displays and crushers, a properly designed crushing plant maximizes productivity and ensures the effective handling of resources. Engineers and drivers style these plants to fit particular site requirements, optimizing factors such as room, product kinds, and expected outputs. By integrating tools like jaw crushers, impact crushers, and cone crushers, a crushing plant can adjust to altering conditions while regularly delivering high-quality items.

Along with these crucial makers, drying systems additionally play a crucial function in handling procedures. A rotary dryer is one such machine that facilitates the elimination of wetness from various products, which is essential in sectors where product quality and service life depend upon dampness degrees. By efficiently drying out materials, rotary clothes dryers enhance the use of minerals and aggregates and stop complications linked with storage and handling.

This operationally simple yet efficient item of equipment is commonly made use of in artisanal and small-scale mining. The use of the wet pan mill simplifies the removal procedure while keeping optimal performance, making it an attractive choice for creating regions.

Roll crushers, while frequently ignored, additionally play a significant function in mineral handling. Their ability to crush materials making use of rubbing and compression makes them suitable for different applications where consistent dimension and granulation are crucial. Roll crushers offer a regular and controlled output, making them extremely helpful in sectors that call for specific bit size circulations.

As we dive right into the interconnected functions of these devices in mining, it ends up being clear how each piece of tools adds to the bigger process of resource extraction and manufacturing. The ideal combination of devices, properly run and kept, can substantially improve productivity, reduce functional expenses, and enhance the overall top quality of the end items.

Real-time information analysis permits operators to make improvements machine performance, maximize process, and decrease downtime. Market gamers are progressively spending in advanced systems that permit for predictive upkeep, reducing unforeseen breakdowns that can interrupt the fragile balance of get more info mining procedures.

Moreover, the environmental impact of mining and accumulation processing can not be disregarded. Striking a balance in between productivity and sustainability has come to be a focus area for lots of companies. Effective equipment like sand washing machines and flotation devices help in maintaining environmental requirements by generating top quality products while decreasing waste. The adoption of greener methods and modern technologies not only boosts conformity with regulations however likewise boosts a company's credibility, a crucial variable in today's market landscape.

Constant advancements in materials science and engineering also promise to improve the sturdiness and effectiveness of equipment. New products that stand up to damage far better can dramatically lengthen the life-span of crushers, mills, and various other tools. This long life converts right into price financial savings over time, making the first financial investment a lot more tasty for services seeking to improve their operational abilities.

To conclude, the world of mining and aggregate processing is intricate and complex. With the combination of various machines, from flotation machines to mobile crushers, the sector proceeds to respond and evolve to obstacles postured by need, environmental regulations, and technological advancements. Each tool offers an important feature within the larger network of operations, making certain that source extraction is efficient, environmentally aware, and economically practical. As we remain to adapt and introduce to brand-new challenges, the future of mining and accumulation handling guarantees to be dynamic and amazing, leading the method for continued development and sustainability in the market.

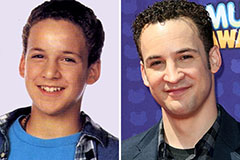

Ben Savage Then & Now!

Ben Savage Then & Now! Jenna Von Oy Then & Now!

Jenna Von Oy Then & Now! Danica McKellar Then & Now!

Danica McKellar Then & Now! Batista Then & Now!

Batista Then & Now! Nicholle Tom Then & Now!

Nicholle Tom Then & Now!